Custom Cases

18 September 2023

Quick Links:

ATA Cases|Pelican Cases|SKB Cases|Shell Cases

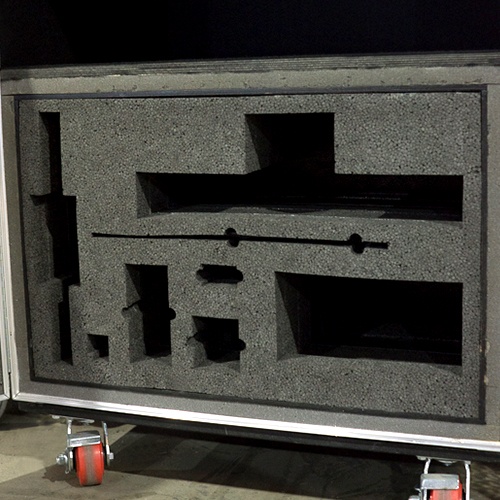

ATA CASE

Protect Your Equipment with a Custom ATA Case

Our high quality, custom ATA cases are designed to protect and move high-value, sensitive, and delicate equipment and instruments that will be routinely and repetitively transported to trade shows, customer demos, sales presentations/events, customer training, music, or sporting events, or for field repair.

At LPC every case is designed and built to meet a unique need. Our engineers are experts at designing a case for how it will be used, transported, accessed, and stored. Because of our extensive experience, we can help you select the right components and give you ideas to improve the packaging of your equipment.

Our ATA cases, and our line of road cases for production companies and events (Kryptonite Cases), are built at our Milpitas CA facility from the highest quality parts. Each case is custom-made to the design specifications. Foam inserts are also customized to ensure the most precise fit for your equipment. A well-fitting foam also presents a professional appearance when your case is opened. Before you receive your case it is inspected to ensure that nothing has been overlooked.

We offer three optional case materials:

HexaGrip—Film Laminated plywood. High quality birch plywood with the outside laminated with a black phenolic pattern and the inside a smooth black phenolic. This high-precision material makes excellent case panels because it is rigid, lightweight, and thin.

High impact ABS—(Acrylonitrile-butadiene styrene) A single-sided plastic laminated to hardwood plywood. The plywood can be solid core or have multiple layers.

FlightPanel plastic—a lightweight polypropylene board, textured on one side. The manufactured cases are 30% to 40% lighter than laminated plywood, although it is not a durable as wood and costs more.

FREE DOWNLOAD

ATA Case Buyer’s Guide

Avoid making mistakes when buying and configuring wood shipping crates.

ATA Case Features and Options

- Incredibly Strong, Durable, and Reusable

- Heavy Duty Recessed Latches and Handles

- Rugged, Extruded Aluminum Alloy, Edge Reinforcement and Tongue and Groove Closure Valance

- Nickel Plated Steel Rivets and Continuous Hinge

- Zinc Plated Heavy Duty Steel Ball Corner Protectors

- Nylon Lid Stays

- Glued and Stapled Edges

- Thermawelded Edges

- Custom Versatility

- ¼”, 3/8”, ½” panel thicknesses

Styles

Customizations

- Custom-fit foam linings

- Doors, trays, dividers and ramps

- Carpet or painted interior

- Forklift skids or casters

- Clean room inner Case

- Rainproof sealing

- Rack-Mount case (with or without shock protection)

- Other requests are welcomed

Features

- Padlockable latch

- Document, trays, and access doors

- Recessed casters

- Swivel casters

- Removable casters

- Skids

- Telescopic handle and Casters

Colors

- Black (Standard)

- Blue (Standard)

- Grey (Standard)

- Red (Option)

- Green (Option)

- Others (Option)

Get your free quote on ATA Cases today!

Ask for a free quote on ATA Cases.

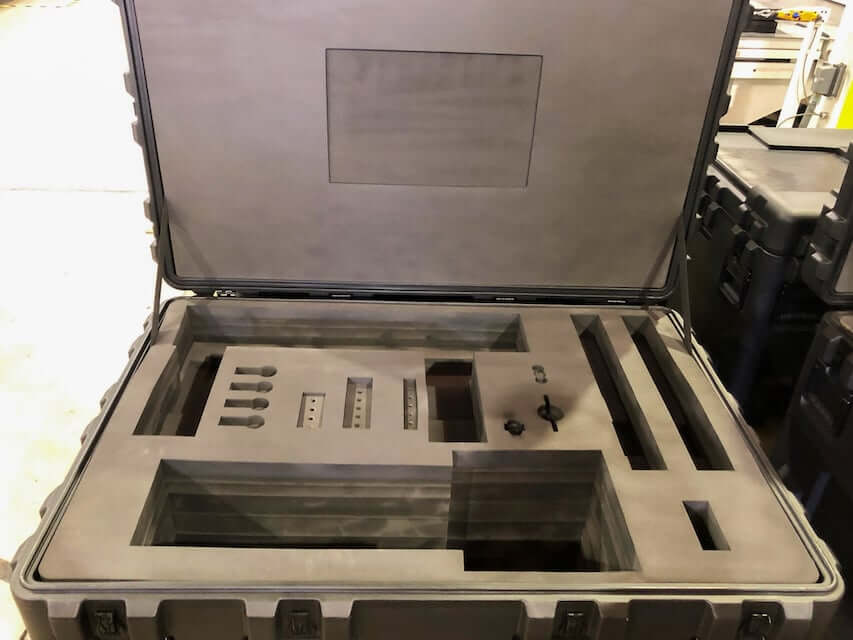

PELICAN CASE

Pelican Cases with Custom Foam Inserts to Organize and Protect

Larson Packaging is proud to be a full technical dealer of Pelican-Hardigg Advanced Case Solutions, and we offer the full/extended line of Pelican products. Pelican is the global leader in designing and manufacturing high-performance protective case solutions. Professionals in the most demanding markets including fire safety, law enforcement, life sciences, defense/military, aerospace, entertainment, industrial, and consumers rely on durable cases.

As one of the few Pelican “Technical Dealers,” we offer the full line of Pelican Products cases — Storm Cases, Pelican-Hardigg Cases, Pelican Air Cases. and more. Pelican and Pelican-Hardigg products are designed and built to last a lifetime, dust-free, watertight and are backed by a lifetime guarantee.

We not only stock the most popular Pelican cases but we maintain large, inhouse inventories of common foams for immediate fabrication for fast turnaround times of even large order volumes. Our lead times are the shortest and the industry and we guarantee our ship out dates for total peace of mind.

Visit our dedicated Pelican Case Dealer website to discover why we are the commercial, industrial and military application specialists for Pelican cases and custom foam.

Different Lines to Meet Your Needs

Pelican Classic, Protector & Storm

- Range of sizes and shapes for unusual and heavy items.

- Withstands multiple uses.

- Interior can be customized.

Pelican Air

- Lightweight but almost as strong as regular Pelican cases.

- Variety of colors and sizes.

- Interior can be customized.

Pelican Hardigg

- Strongest cases for heaviest equipment.

- Interlocking and stackable models (ISP).

- Many custom options are available.

- Casters, handles, latch options, etc.

We design and manufacture custom foam interiors inhouse at our state-of-the-art facility

While the rugged Pelican Case protects your product from external impacts, the foam interior braces your product and subcomponents and protects them from shock and vibration.

At the Larson Packaging Company, we specialize in designing and manufacturing inserts for Pelican cases. We use foam engineered and appropriate for your unique need, whether special non-abrasive, water-resistant foam, special ESD foam to protect sensitive equipment from discharge or foam that won’t degrade over the life of your case and product.

A custom foam is also the perfect way to:

- Isolate and protect individual parts or sub-assemblies

- Improve access to equipment through organization

- Present a professional image

- Provide the proper cushioning for your application

GOT PELICAN CASE QUESTIONS?

Get The Complete Pelican Case Buyer’s Guide

SKB CASE

SKB Cases for Military and Industrial

Military, Aerospace and Industrial SKB Case Specialists

When you need custom solutions, Larson Packaging Company can tailor SKB Mil-Standard cases for your packaging needs. SKB Cases have been among the leading molded polymer transport cases since 1977, and LPC is an official authorized dealer. SKB constantly works to improve their designs in order to protect sensitive equipment with strong, durable cases.

Built to meet or exceed military specifications, SKB roto-molded and injection-molded cases are independently tested for quality and durability and have been engineered to provide the best protection and functionality for many industries. We customize a full line of industrial SKB cases (including rackmount models) for military, medical and entertainment equipment. We also design and manufacture custom foam inserts and cushioning systems to protect your product.

iSeries Cases

SKB military-grade waterproof and dust-tight design. These injection molded cases are resistant to impact damage, UV, solvents, corrosion, and fungus (MIL-STD-810F). iSeries cases are built for high impact strength with a lightweight and durable design for travel and storage protection.

Single Lid Full Product Line

Rack Cases Full Product Line

Custom Foam Inserts for SKB Cases

We specialize in the design and manufacture of custom foam inserts for hard cases. We work with common and specialty foams such as Ethafoam, cross-linked or beaded polyethylene to organize and protect your products, including “class A” surfaces, from shock and vibration, and other factors that can damage your equipment such as abrasion. At LPC, our design engineers work closely with you and with our manufacturing floor to ensure that your packaging will fit and perform as specified.

Foam Design and Manufacturing

Our capabilities include rapid prototyping, complex assembly, diecut, contour-cut, CNC-routed, and waterjet-cut foam. We can build precise foam assemblies either from your own designs and CAD files, or we can create a prototype for you. Whether you have an idea, a physical sample, or a SolidWorks model, we can engineer a concept for you to review, and we can develop it from prototype to final production.

How SKB Cases Protect Your Equipment

SKB uses non-recycled plastic to produce cases with no added bulk, making them lighter in weight and up to 3X stronger than other hard cases, with less tendency to crack or warp –– all at a competitive price point.

- Field replaceable components include knuckle-friendly “trigger” latches, “one touch” pull handles, and molded-in hinges

- Gasket-sealed waterproof design

- Made from high-strength polypropylene copolymer resin

- Built to meet or exceed military specifications, and independently tested for quality and durability.

Larson Packaging Company also manufactures custom foam inserts for SKB cases to give your product precise protection in transit. Different foam types and densities are available.

SHELL CASE

Shell Case with Custom Foam Inserts for Lightweight Protection

Larson Packaging Company is a stocking dealer of custom Shell protective cases. Shell is a leading manufacturer of OEM carrying solutions, with a sleek line of fully customizable and brandable soft-shell cases. We specialize in manufacturing custom foam interiors for shell cases and can custom-design foam trays and cavities to fit different components using various foam types and densities.

Custom Foam Inserts for Shell Cases

Larson Packaging Company designs and manufactures custom foam inserts on premises, utilizing different types of common and specialty foams including Ethafoam, cross-linked or beaded polyethylene. When you customize your shell case with foam inserts, our design engineers work closely with you and with our manufacturing floor to ensure that your case provides optimal protection and shock absorption designed for the case.

Foam Inserts Designed and Manufactured

Our capabilities include rapid prototyping, complex assembly, diecut, contour-cut, CNC-routed, and waterjet-cut foam. We can build precise foam assemblies either from your own designs and CAD files, or we can create a prototype for you. Whether you have an idea, a physical sample, or a SolidWorks model, we can engineer a concept for you to review and develop it from prototype to final production.

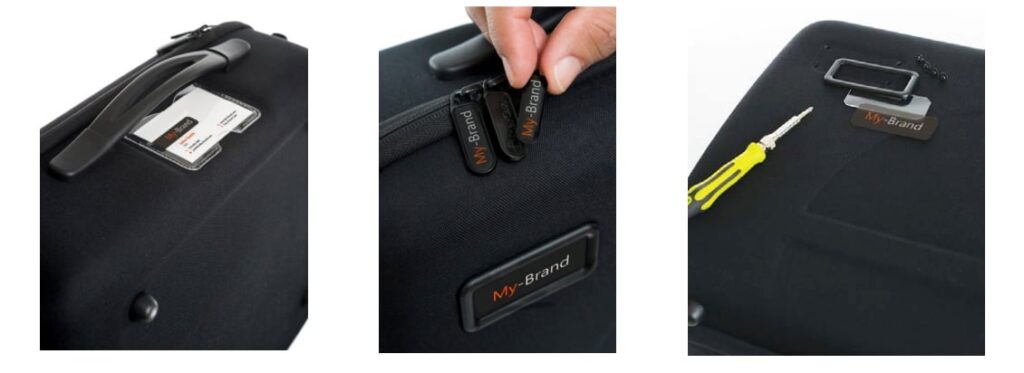

Sleek and Stylish Carrying Cases

Shell cases are a great solution when you need a customizable protective carrying case that showcases your brand. Composed of thermoformed shells with heavy-duty water resistant textile layers, zipper closer and internal foam tray, they are used to protect medical devices, electronics, measuring devices, optical devices, sales demo kits and more. In addition, they are fully customizable with brandable logo plates, brandable zipper puller, and card holder for easy personalization.

Variable Sizing

Many different sizing options are available. The shell case standard 300 series, which LPC carries, includes the following cases that our team can modify with custom interiors and foam:

- Standard 311 (8.6 x 5.3 x 3.5)

- Standard 315 (10.2 x 7.4 x 3.9)

- Standard 320 (11.6 x 9.4 x 4.1)

- Standard 330 (14.1 x 10 x 5.9)

- Standard 335 (15.9 x 12.5 x 5.5)

- Standard 340 (16.1 x 13.7 x 6.1)

- Standard 350 (18.5 x 15.3 x 6.8)

Easy Branding and Customization

Do you want your cases to reflect your brand and help showcase your company? Shell cases are easily brandable with customizable logo plates, zipper pullers, and custom card inserts to highlight your unique brand.

Shell Case Hybrid 500

The Shell Case 500 is a hard shell case engineered to be strong and lightweight. Made of a durable polycarbonate material, the outer shell is extremely light and strong, offering optimal protection for the contents inside. Our team can help you customize internal foam dividers and cushioning so your product is safely and conveniently transferable in these durable cases.