IndUStries

Custom protective packaging solutions for Medical Devices and Life Sciences equipment

We understand the unique challenges of medical devices and life sciences

Medical and life sciences devices are frequently destined for hospitals, clinics, doctors’ offices, or laboratory environments, where access for unloading can be difficult and the packaging itself may need to be returned and reused, stored for later use or recycled at the point of delivery.

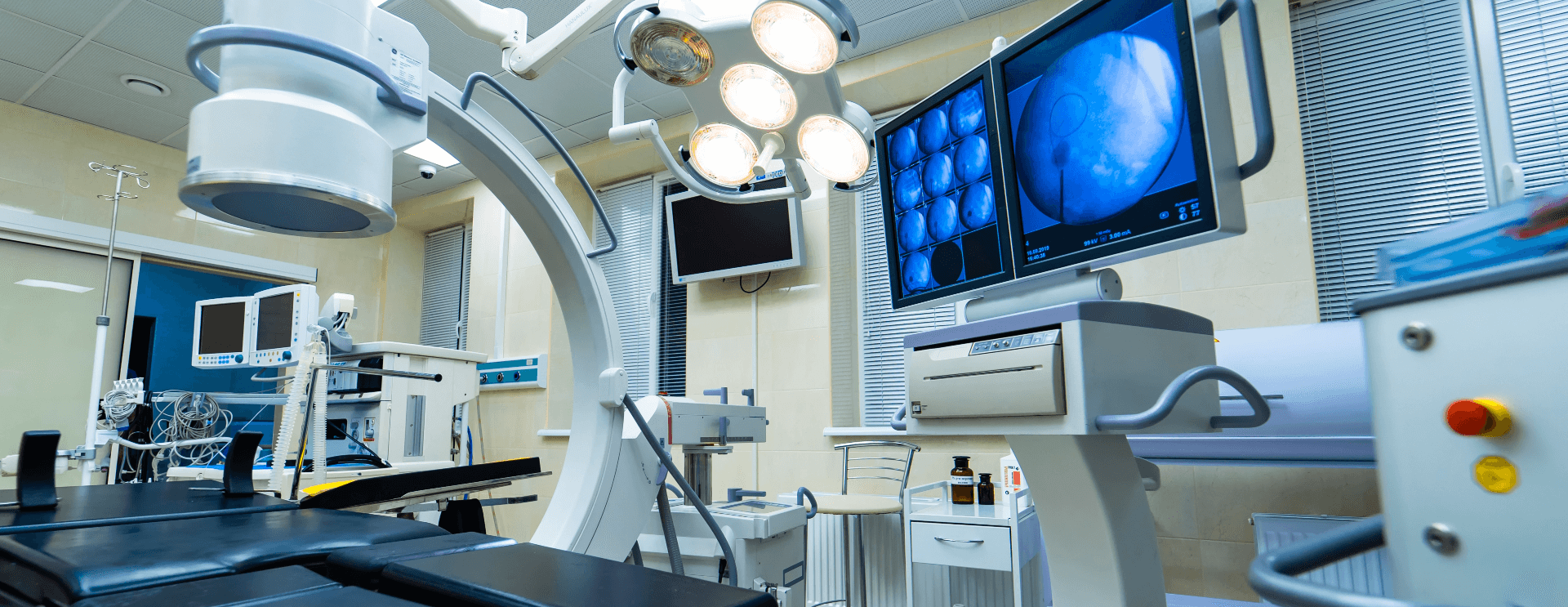

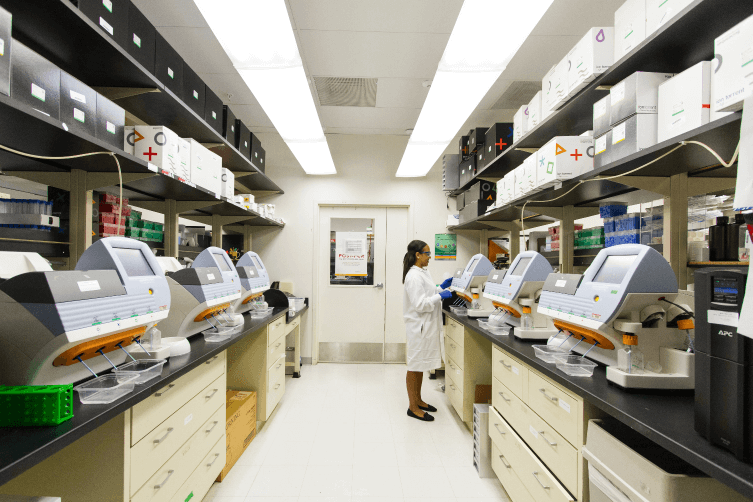

Our packaging engineers are experts at designing packaging for highly sensitive yet oddly shaped and/or oversized medical devices. This includes CT scanners, MRI and dialysis machines, robotic surgical machines, dermatology and ophthalmology devices and a wide array of lab testing equipment that requires specialized cushioning systems and shock indicators to monitor and record levels of shock and vibration during transit.

We also manufacture custom packaging for FRUs and LRUs for these devices and quality cases to assist in displaying and demonstrating equipment at tradeshows, conferences and events.

We specialize in designing systems to efficiently and safely load and unload cart-based devices without damage or injury, and pay particular attention to componentry such as casters that require careful blocking and protection to hold them — and the product — in place during transit.

And we partner regularly with manufacturers of Class II and III medical devices and understand the special quality requirements of packaging used to ship medical equipment. We operate to stringent quality standards and can manage large packaging projects to ensure our quality system aligns yours. This includes shipping requirements such as legible and easy identifiable labelling on the shipping packaging and moisture-resistant wrapping of the equipment inside the crate.

Custom server crating

Foam and box solutions designed and manufactured under one roof

Custom shock and vibraiton solutions

Supports and inserts made from Polyethylene, Polyurethane, Polypropylene, Anti-static and Cross-linked foam

Technical Packaging Dealer

Application-specific Pelican-Hardigg and SKB Case solutions

Case and crate customizations

Cradles, wheels and casters, handles, inspection ports, hardware, colors, heat-treated and reusable designs

We design and customize crates, hardcases and hybrid foam boxing to protect and transport all types of high-value and fragile medical devices and equipment

- Blood Analyzers

- Dialysis Equipment

- Gene Sequencing Equipment

- Laboratory Equipment

- Surgical Robots and Devices

- Dermatology Devices

- Optical Test Equipment

- Ophthalmology Devices

- Monitors

- Computers

- Peripheral Devices

- Orthopedic Beds

- Carts

Case studies

-

Simple optimizations save 47.5% on medical company’s crate costs

The customer, a medical device company in home dialysis machines desperately needed to find cost savings on a… Read More

-

Three failed crate design attempts elsewhere led robotics manufacturer to LPC for a clever solution

Working with a packaging distributor and their customer, a leading surgery robot designer/manufacturer who asked us to redesign… Read More

-

Rapid design and deployment of scientific blood analyzer for medical applications

A medical company needed protective packaging to help it rapidly deploy a delicate blood analysis device during the… Read More

-

New Hybrid packaging design saves client $191 per crate and reduces shipping expenses

Hospitals and healthcare providers need reliable shipping solutions for high-value medical devices. Due to the critical importance and… Read More

-

Crate redesign for medical device streamlines delivery process and saves 50% in packaging costs

Packaging and shipping is often a complex logistical exercise for manufacturers and distributors of medical devices due to… Read More

-

Packaging redesign cuts transshipment damage costs by $200,000

This leading pharmacy automation and robotic manufacturer was troubled by damage consistently occurring during transhipment to its products…. Read More