IndUStries

Robust, shock-resistant protective packaging designed for Electronics and Communications

We understand the unique challenges of electronics and communications

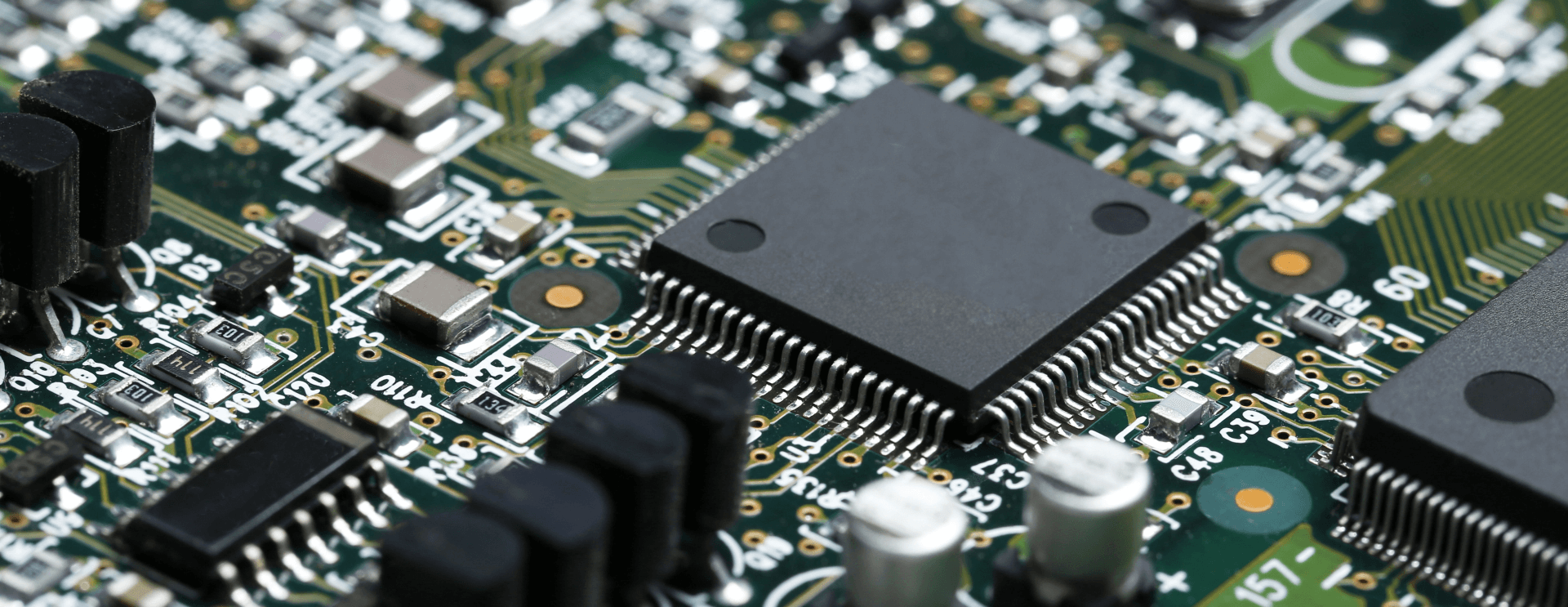

Modern devices — especially those containing integrated circuits — are very vulnerable to shock and the sudden and momentary flow of electrical current.

While the damage shock and vibration can easily do sensitive electronic equipment during transit is well known, many packaging suppliers overlook the risk of electrical discharge. This discharge might be imperceptible to humans, but it can easily break sensitive electronic devices.

Our engineers are specialists in designing custom electrostatic discharge (ESD) foam packaging to protect delicate electronic components such as printed circuit boards from ESD damage and maintain product quality and reliability during transit. They also intimately understand the shipping safety requirements of lithium battery components. This, coupled with our precision-engineered in-transit shock and vibration protection, assures your valuable electronic and communications equipment will get to its destination safely.

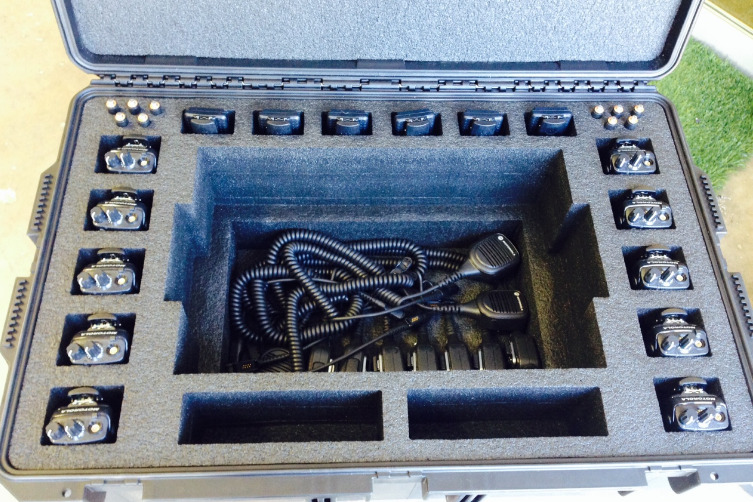

They also understand when pre-made rack cases can be used for mobile communications and systems, when box and foam is going to be more suitable, and the weight at which you ought to consider mounting your product to a pallet. We can even provide branding and printing on the external surface.

Sometimes electronics cargo isn’t even particularly fragile. Our engineers know the difference and will ensure foam inserts are well-designed and include additional protection for accessories such as rack rails, cables or manuals as required.

Or we can apply our expertise as one of the USA’s few full technical dealers for Pelican-Hardigg cases and an authorized technical dealer of SKB Cases to customize a hard case and design an integrated packaging system of waterjet-cut slotted foam to make packing and unpacking small, delicate items easy.

Quality assured

All of our manufacturing facilities are ISO9001:2015 certified

Any shape or size

Specialist expertise in protective packaging to support extremely sensitive, fragile, and odd-shaped equipment

Cleanroom-grade

Packaging solutions suitable for cleanrooms, and handling hazardous materials

Custom shock and vibration solutions

Floaterbases, supports and inserts made from Polyethylene, Polyurethane, Polypropylene, Anti-static and Cross-linked foam

We design and customize to protect and transport all types of fragile and sensitive electronic communications equipment

- Integrated Circuit Boards

- Tactical Gear

- Security Systems

- Surveillance Equipment

- Long Range Acoustic Devices

- Monitors

- Communications Systems

- Mobile Control Centers

- Mobile Medical Supplies

- Portable Lighting

Case studies

-

Inhouse CNC machining reduces case lead time from weeks to days

A company approached Larson Packaging Company with a problem. Their Pelican case required precision drilling of two holes… Read More

-

Clever redesign leads to lighter, more robust and more visually appealing SKB custom case solution

A professional streaming service came to Larson Packaging Company with a design challenge for their Apple TV box,… Read More