Unite all your custom anti-shock and anti-vibration protective packaging under one roof

For faster turnaround times, simplified admin coordination, and a frictionless vendor experience.

CASE STUDY

Packaging redesign saves $200k+ p.a.

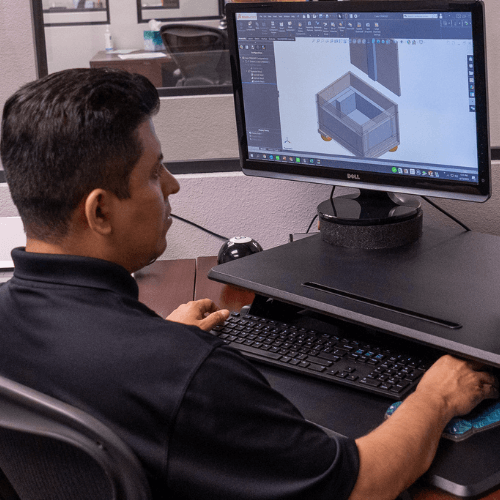

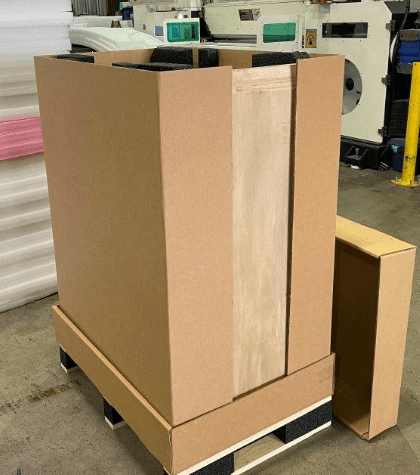

A simple packaging redesign and optimization cut transhipment damage costs by $200,000 for this Californian robotics manufacturer, and reduced packing time from 30 minutes to just 3 minutes. The new packaging program runs with less than 1 FTE focused on the packaging, which allowed the customer to redeploy headcount and focus on their core business.

Saved $200k per year in product damage

The new crate design slashed packing and shipping times from 30 minutes per package to just 3 minutes.

Reduced inventory by $50k with no late shipments

A dramatic reduction in warehouse floor space used for packaging