Foam solutions for ESD (electrostatic discharge applications)

23 April 2024

Modern devices — especially those containing integrated or exposed circuits — are vulnerable to sudden and momentary flow of electrical current. This discharge might be imperceptible to humans, but it can easily damage sensitive electronic devices.

One particularly susceptible category are lithium batteries as they can easily short circuit and catch fire. This is why they are classified as dangerous goods under class 9, United Nations. Other components susceptible to electrical discharge damage include integrated circuits, microprocessors, memory chips and assembled electronic devices.

How to protect components from ESD

The two factors that have the greatest impact on preventing an electronic discharge during storage and transit are:

- Design of the interior packaging

- Choice of foam

Design Considerations

While the outer packaging is designed to protect from external impacts and the elements, it is the interior foam insert that protects the component most from shock, vibration and discharge. The foam insert should be designed to perfectly hold the components in place and prevent movement within the box or crate. It’s also important for the foam insert to isolate and protect individual parts or sub-assemblies. For example, nonconductive material should always be placed between lithium batteries to stop movement and prevent them from touching and potentially discharging.

Our engineers are specialists in designing custom ESD foam packaging for control programs to protect delicate electronic components from ESD damage and maintain product quality and reliability.

We can design and fabricate all types of ESD foam packaging and inserts in a variety of shapes and sizes, including sheets, blocks, and custom-cut shapes to deliver the appropriate shock and vibration protection requirements of your sensitive electronic devices.

And we can do it for all types of packaging including corrugated and plastic boxes, hard cases and ATA cases.

Foam choice

There are many different types of foam that can be used for ESD applications. Your packaging engineer will be able to tell what foam is best for your application taking into account the components being shipped, their sensitivity to shock and vibration and level of ESD protection needed.

Here are a few of the more popular ESD foams used.

Conductive Crosslinked foam

An effective replacement for silver ESD bags and acts as a faraday cage when an item is fully encapsulated. Not recommended for batteries since it will drain them if positive and negative terminals are both in contact with the foam.

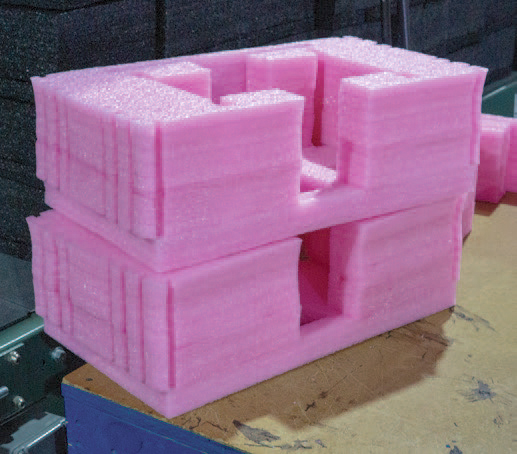

Pink Antistatic Polyethylene and Polyurethane foams

These standard foams contain additives to provide long life antistatic properties and prevent friction based electrical charge generation.

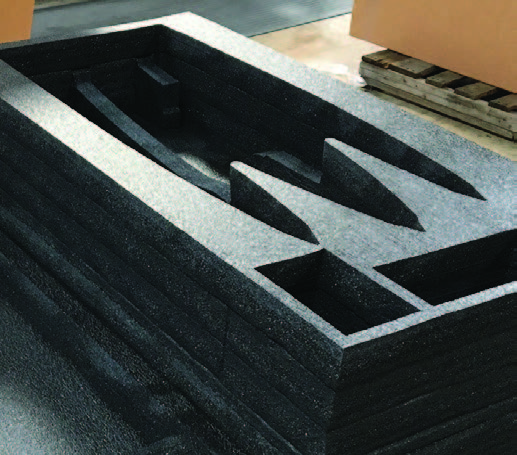

Black Static Control foam

Provides the same protective ESD properties as pink antistatic foam but without the shelf life limitations. Though Static control and conductive foams may look and feel similar, static control foam is not known to drain batteries.

Download our EDS Capabilities sheet

Foam solutions for ESD (Electrostatic discharge) applications, designed to keep sensitive equipment and instruments safe from damage.