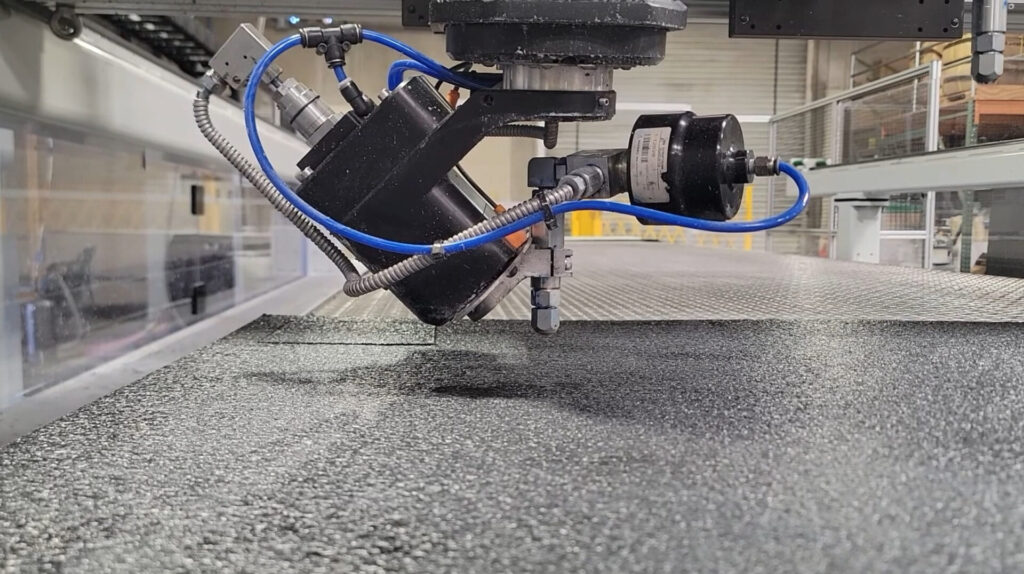

This new high-speed WARDJet waterjet cutter enhances our ability to manufacture fast and meet shipping guarantees while maintaining exceptional quality

26 September 2023

We recently installed new, state-of-the-art equipment from manufacturer WARDjet in our facility. The WARDJet J-106 waterjet cutter is a high-speed water-only machine purpose-built to process foam, rubber and other soft materials in high volumes with incredible precision.

Water-only waterjets are a relatively new concept for many companies, but WARDJet has years of experience with these systems. Their J-106 machine gives LPC industry-leading cutting-head acceleration, 5-axis cutting, impressively quick material handling, and features highly efficient waste management.

The WARDJet J-106 Waterjet Cutter Specifications

Our new WARDJet J-106 waterjet cutter excels at precisely cutting common packaging materials such as polyethylene foam, neoprene, polyurethane foam, ABS, PVC, PVC foam, HDPE and plywood at lightning speeds, enhancing LPC’s ability to manufacture premium-quality custom protective packaging fast, accurately and on-time.

| X-Y cutting area | 10 ‘ x 6’ |

| Z-Axis travel | 10″ |

| Drive | High-precision rack and pinion (X&Y) ball screw Z |

| Linear positional accuracy | +/- 0.010” per axis |

| Repeatability | +/- 0.005” per axis |

| Speed | 0.01”-2,500” per minute |

The WARDJet J-106 Waterjet Cutter Key Features

CUTTING-HEAD SPEED

The ability of the J-106 to accelerate quickly between cuts, known as rapids, is vital to cutting as many parts as quickly as possible. At speeds of 1000 lpm means we can cut many small parts fast. Plus, our machine features multiple heads which increases production capacity even further.

WATER-ONLY SYSTEM

A pure, water-only system that does not use abrasives has a narrow kerf that does not alter the intrinsic properties of the material being cut.

5-AXIS CAPABILITIES

Many water jets can only cut 90 degrees. The J-106’s 5-axis cutting head lets us cut complex shapes such as cones, polygons and other polyhedronal shapes. Chamfers and bevels can also be added to a packaging part without the need for time-consuming secondary processing.

STACKING AND COMMON LINE CUTTING

When processing foam on a waterjet cutter, stacking and common line cutting techniques become possible. Stacking multiple foam layers allows them to be cut simultaneously, potentially cutting manufacturing time in half. And since the kerf created by water-only cutting heads is so small, a single cut can be used to create the edges on two neighboring parts — common line cutting.

What does this mean for you?

It means perfect foam cuts with no concavity or material deformation!

Foam can be a tricky material to cut because it is easily damaged and deformed. What’s more, conventional die cutters need to compress the foam to create a clean cut.

Typically, this leaves a small reverse indentation or concavity. Of course, this usually is irrelevant to industrial applications. But, for certain applications such as high-end and upmarket case interiors, presentation is as critical as cushioning. Ragged cuts to foam sets that have been caused by CNC machining can be devastating to the aesthetic appeal you’re aiming for.

Waterjet cutters deliver a perfect cut with zero concavity every time because they use a non-contact form of cutting that creates minimal downward pressure on the material. There’s simply no risk of compressing and deforming the material. And, because it’s a cold-cutting process, there is also no risk of burning or marring foam materials.

Faster One-pass Production

A typical conventional die cutter can process foam thicknesses of no more than two or three inches. Furthermore, it cannot cut ABS, PVC, HDPE or plywood at all. This means a tedious layer-by-layer cutting process with multiple passes of the packaging material and time-consuming post-cut processing steps.

Waterjet cutters can process much thicker foam. The WARDJet J-106 can cleanly cut foams as thick as 7 inches in a single pass. Plus, it will cut up to ½” thicknesses of ABS, PVC, PVC foam, HDPE and plywood. A conveyer belt table and sensor-based controls automate material loading and can handle either large rolls or flat sheets. This delivers us a 30-50% improvement in processing speed and a corresponding reduction in manual labor making it even easier to meet rapid turnaround times.

Complex Foam Designs in One Pass

Without the benefit of a 5-axis machine, cuts that aren’t at 90 degrees must be done on other machines, or manually. This adds a time-consuming secondary step to complete the conversion of a part. A classic example would be the foam side wall chamfer necessary to make the foam insert sit snugly inside its box.

The WARDjet J-106 waterjet cutter can cut all angles with super precision and predictable quality in a single operation. Even for extremely complex protective packaging and cushioning, there’s no manual joining and gluing, and no unnecessary joins or weak points.

Better For your Product; Better For The Environment

Many waterjet cutters use abrasives (typically fine-grained garnet) in the stream of water that’s used to perform the cutting. This eventually enters the waste stream and in the worst scenarios trace amounts can be left on the foam and contaminate your product. The J-106 is a pure, water-only systems and thus eliminates that risk, and removes a potential environmental contaminant from our manufacturing process as well.