Are Your Wooden Shipping Crates Made with Precision Engineering?

12 February 2015

If answering the question posed in the title of this blog was difficult for you, you’re in good company. When your equipment (rack systems, medical devices, lasers and optics, robotics, etc.) is delivered without a hitch, you know that it was packed and handled correctly, but do you know why? Or if it was just luck? Conversely, if something goes wrong do you know what questions to ask your shipper? Can you zero in on what went wrong with the shipping crate so it doesn’t happen again? Can you prevent it from happening before the fact? Understanding the art and science of building wooden packaging is one of the best skill sets you can acquire to protect your valuable cargo.

» Read More 5 Things You Need to Know About Shipping Rack Server Crates

Expect a Silver Lining

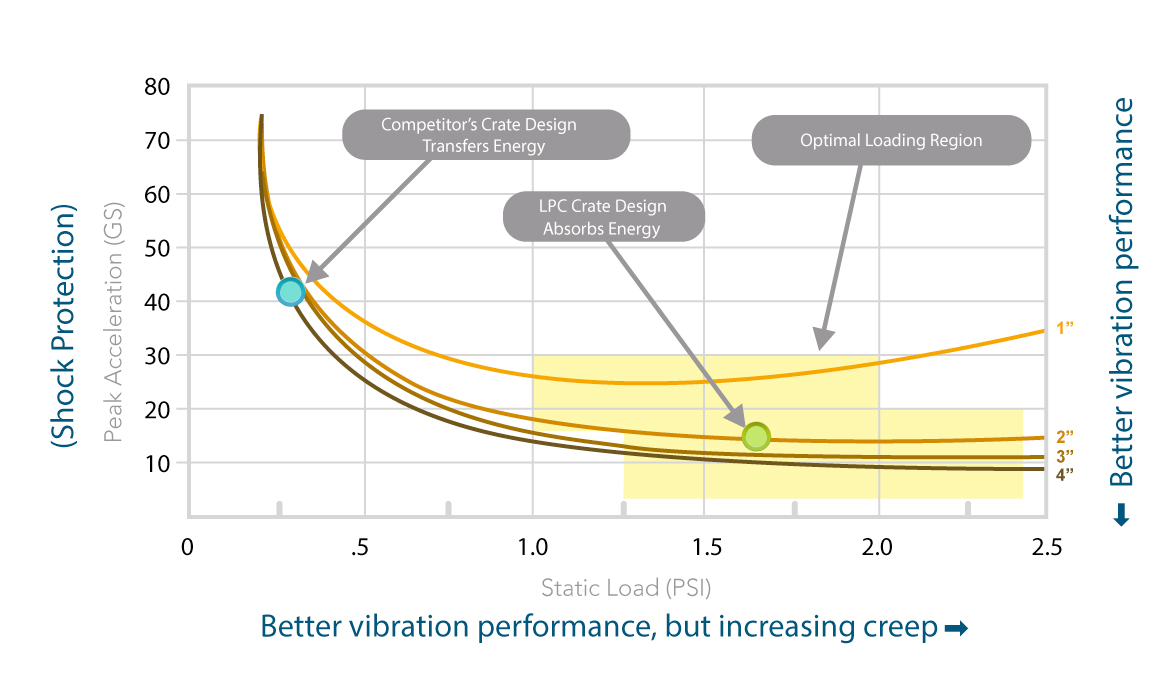

There are many elements involved in creating safe, durable wooden shipping crates and ATA cases for your high-end electronics. One of the more important of these is the foam cushioning that creates a spring or dampening system between the outside crate and the equipment inside. This foam is employed to mitigate against vibration and protect against shock. It’s therefore easy to assume that greater amounts of foam will equate with greater defense against damage. Unfortunately, this is not true. In fact, optimal foam cushioning is determined through a complex calculus (the foam curve) that identifies that precise loading condition, or the point of greatest energy absorption. See Chart Below Working with a packaging partner like LPC can both reduce excess packaging costs (like excess foam) and create a more reliable delivery experience.

» Read More Wooden Shipping Crates & Packaging: Balancing Cost and Quality

Foam Cushion Curve

There’s More than Nuts and Bolts to Packaging

It’s not uncommon for packing and shipping companies to employ safety bolts for rack server crates to keep the foam from separating from the floater. Applied properly, with the right adhesive, separation is highly unlikely. In addition, the bolts can become a conduit for shock and vibration, negating the benefit of the foam for the floater. Selecting a company with in-depth knowledge of the myriad variables involved in crating rack servers is essential to a successful outcome. Choose a company like LPC that relies on experienced engineers and a scientific approach to providing optimal solutions.

» Read More Use Cost-Per-Trip Model When Costing Out Wood Shipping Crates