Advantages of expanded polyethylene foam vs cross-linked polyethylene

25 September 2018

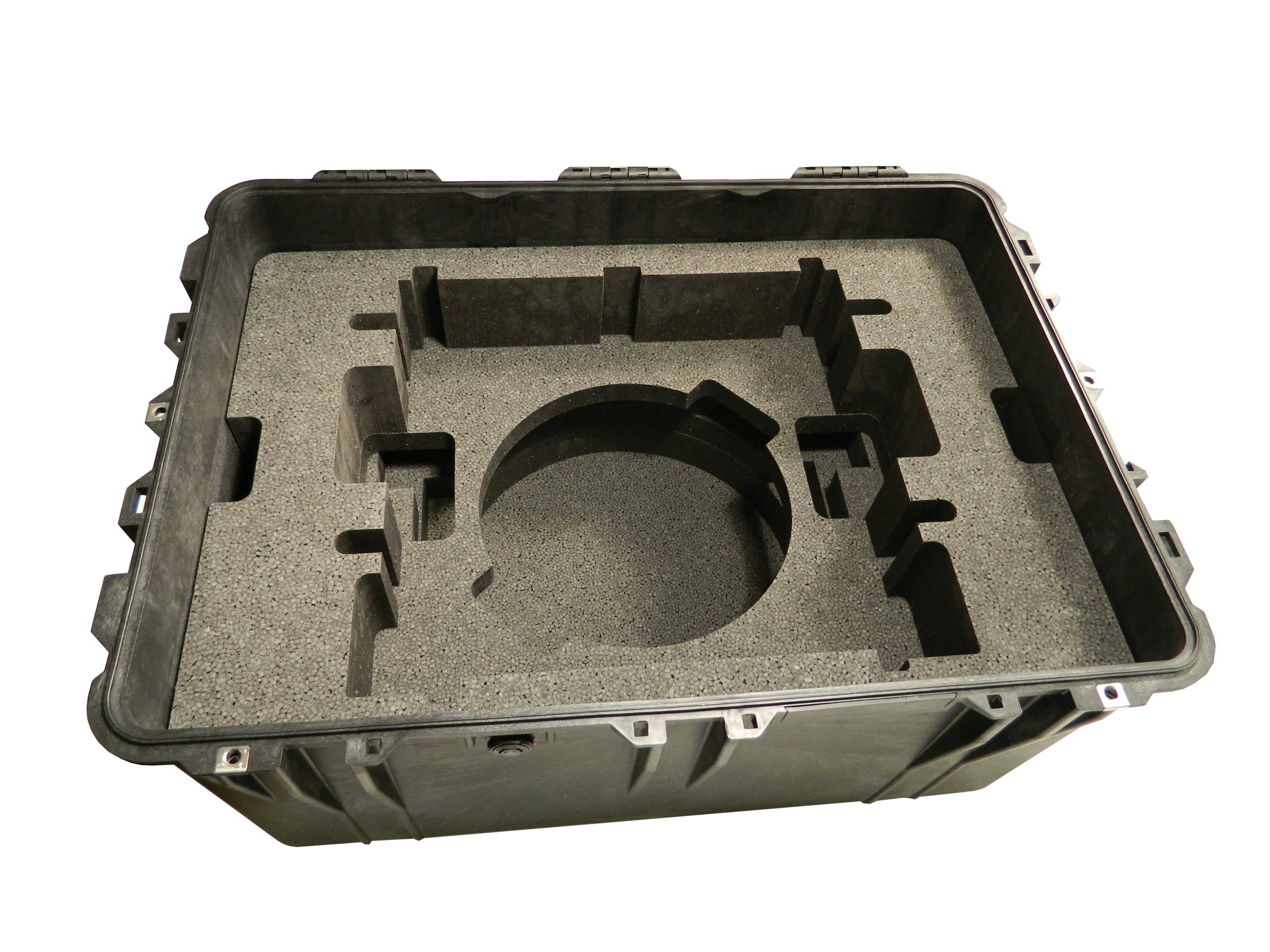

When considering high performance foams for custom industrial packaging, expanded polyethylene foam (aka EPE or BPE) has several subtle but meaningful advantages over cross-linked polyethylene (aka XLPE) which result in superior packaging protection, cost savings on foam, and a lighter pack and is recyclable. Since both EPE and XLPE come from the same resin (PE) and both are molded buns or planks, one would expect the properties to be identical, but differences in the manufacturing process make EPE superior for a variety of packaging applications such as medical equipment, semiconductor equipment, IT servers, automotive class A surfaces, robotics, and other instrumentation.

Advantages of EPE over XLPE

Higher strength to weight ratio.Because of the way EPE is manufactured, the structure of the foam is isotropic, making the foam equally strong in all directions. For example a piece of EPE with a density of 1.5 (EPE #1.5) has thesame compression,greater tear resistance, and is 25% lighter than a similar piece of higher density XLPE #2.0. All of this results in better dynamic cushioning and protection for your product during shipping, as well as a lighter pack. Also, the density of EPE is uniform whereas the density of XLPE can vary from skin to center by as much as 40%.

![]() 100% recyclable. all EPE scraps and pieces are easily recyclable in a foam densifier. XLPE is not easily recyclable and typically ends up in landfill.

100% recyclable. all EPE scraps and pieces are easily recyclable in a foam densifier. XLPE is not easily recyclable and typically ends up in landfill.

Odorless and non off-gassing. EPE is inert and does not off-gas or produce an odor, whereas XLPE that is chemically crosslinked (ie manufactured with peroxide) may off-gas or leave an odor affecting the presentation or even damage your product or equipment. Off-gassing may potentially damage optics or other sensitive equipment.

Find out more about the superior properties of EPE Beaded polyethylene foam packaging excels in many applications.

Work with your packaging partner to select the right foam for your application.

Selecting a packaging partner with knowledge and experience about the performance properties of various foams can improve your packaging. At Larson Packaging Company, our design team can help you identify the correct type, amount, and density of foam to ensure that your product will always arrive safely.