A Primer on Industrial Crates

18 July 2014

Wooden shipping crates and heavy duty skids are designed for the size, weight, shape, fragility, sensitivity and destination of the items to be shipped. They may include floater bases and foam lining or supports for shock and vibration protection. Specialty hardware, blocking and ramps may be included to facilitate reuse or loading. Over design means paying for more wood, hardware and labor than you need, and under design can lead to damaged equipment and other consequential expenses.

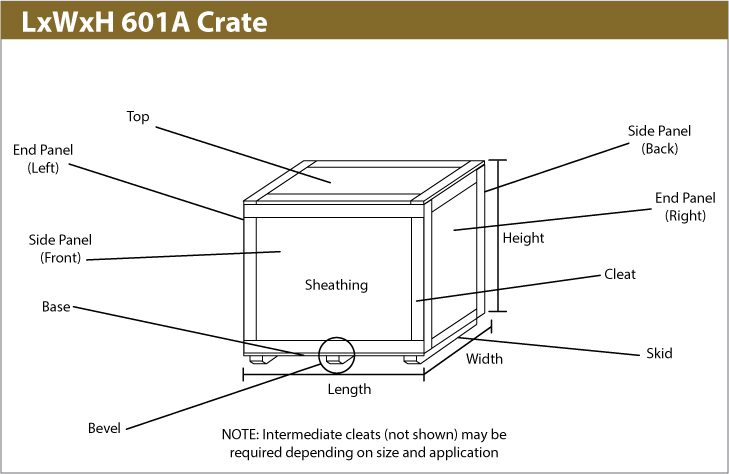

The majority of industrial crates are the 601A design (see Figure 1). These are a light duty wooden shipping crates suitable for most purposes and can be strengthened with intermediate cleats (additional boards between the edge cleats) and/or thicker sheathing (the wood, usually plywood, that makes up the four panels and the top.)

When top loading is difficult or front loading desirable, or if the item to be crated is heavy or bulky, a 601A D/E (Drop End) crate may be called for (See Figure 2).

Once the item is on the base, the cap (the top, two sides and two ends) is placed over it and fastened to the skids, usually with lag screws. Depending on the type and weight of the item, the base may be plywood or lumber.

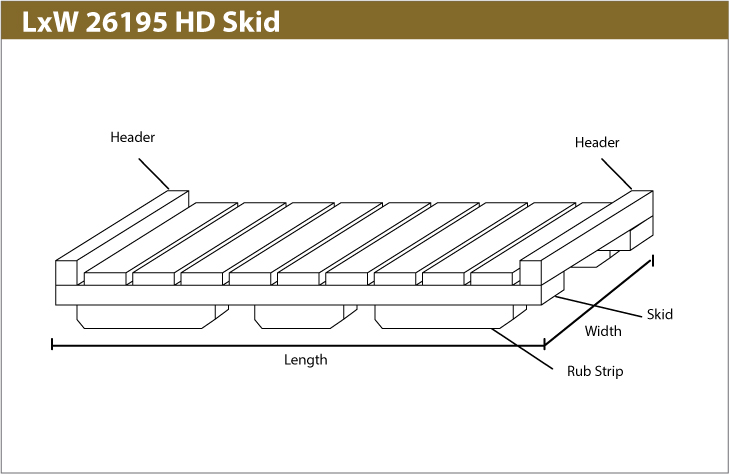

Depending on what you are shipping, whether it is a box, a sensitive product, a machine, or miscellaneous items, you might need just a pallet or a skid. A pallet with no bottom deck boards is called a skid (see Figure). Skids also refer to the timbers under a crate or base that allow for forklift entry. Or you may require full protection from the elements and potential damage, which requires a crate. In some cases, a base with a corrugated sleeve or cap may be sufficient. Risers, rails, removable supports or blocking, and ramps to facilitate loading and unloading, may be useful or required.